-

- solid-liquid separation series

- industrial filter cloth

- filter press filter bag

- centrifuge filter bag

- leaf filter filter bag

- belt type filter press filter cloth

- flat fold filter filter cloth

- vertical disk filter filter bag

- flat filter filter cloth

- drum filter filter cloth

- suction filter filter bag

- liquid filter felt

- liquid filter bag

| Liquid filter bag | |||||||||

| 2019/8/27 10:01:50 阅读次数:794 | |||||||||

|

|||||||||

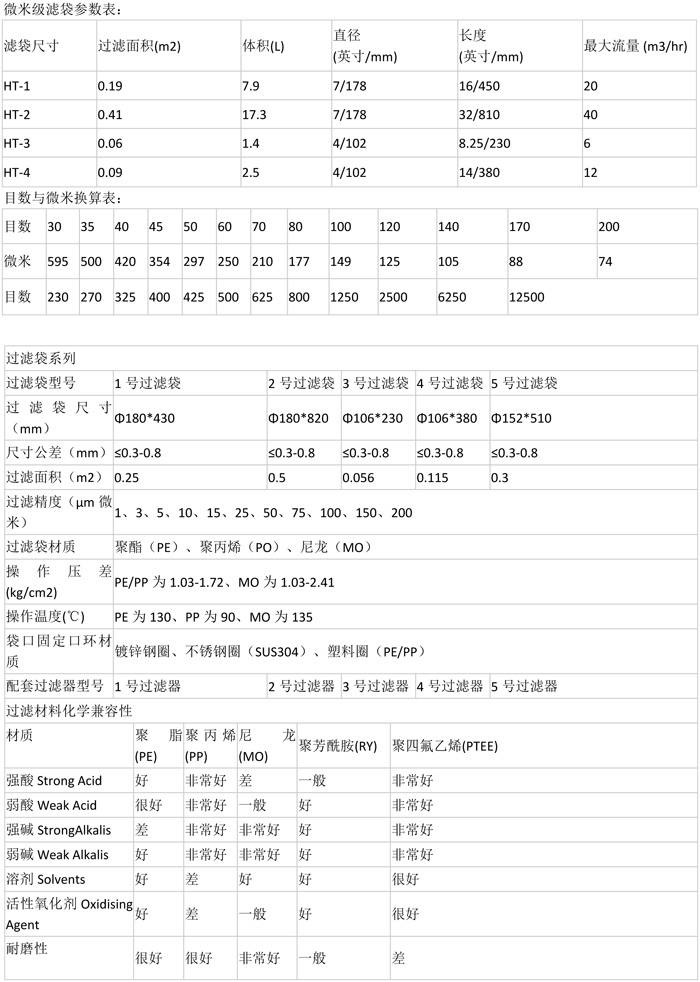

The description of the liquid filter bag:

The company has from the fiber filter bag one-stop production lines, processing to the finished product is the size of the domestic is quite high precision micron grade liquid filter bag manufacturer of technology. Choose filter import and domestic high-quality raw materials, the use of advanced processing technology, strict quality control, can provide customers with tailored for technical solutions. Leading developed a high-precision anti sliding sideways steel welding filter bag. Make sure that our liquid filtration material does not contain silicone oil, to ensure its application in food or coating demanding occasions.

|

|||||||||

| Previous:无 | next:Nylon liquid filter bag | ||||||||

chinese

chinese English

English