-

- solid-liquid separation series

- industrial filter cloth

- filter press filter bag

- centrifuge filter bag

- leaf filter filter bag

- belt type filter press filter cloth

- flat fold filter filter cloth

- vertical disk filter filter bag

- flat filter filter cloth

- drum filter filter cloth

- suction filter filter bag

- liquid filter felt

- liquid filter bag

| Liquid filter bag | |

| 2017/12/21 22:10:36 阅读次数:662 | |

|

|

Description of liquid filter bag:

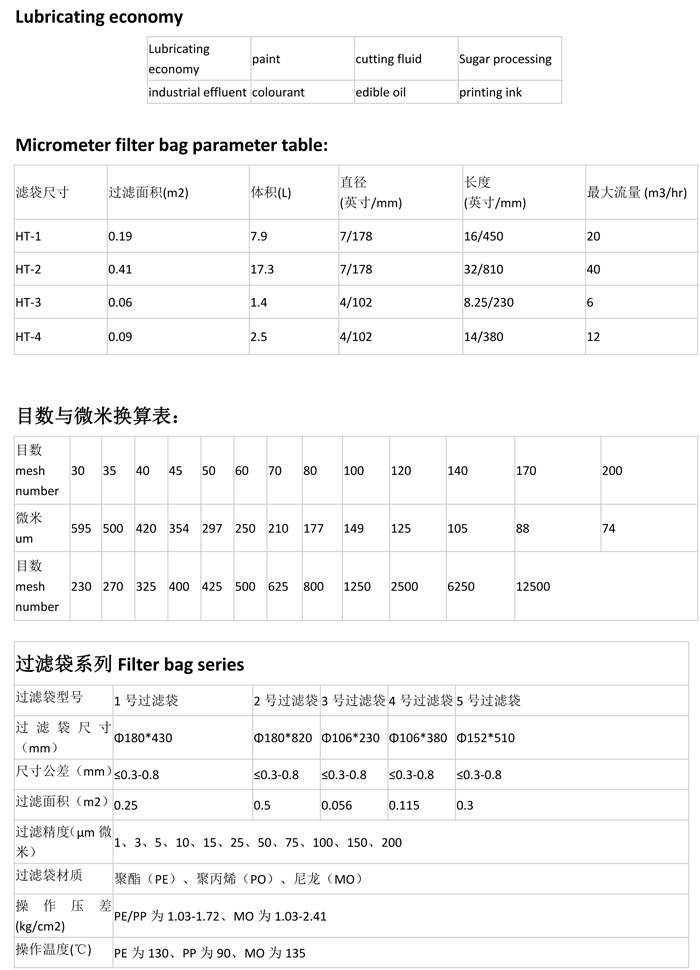

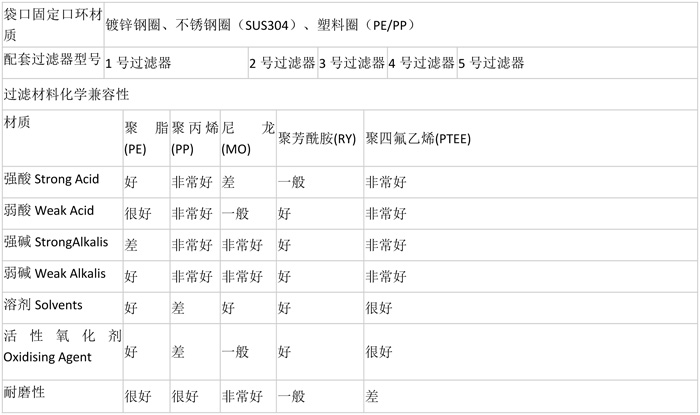

The company has from the fiber bag processing to finished one-stop production line, is a high precision micron liquid filter bag production technology has a considerable scale of domestic manufacturers. The high-quality imported and domestic filtration of raw materials, the use of advanced processing technology, strict quality control, can provide tailored technical solutions for customers leading. The development of high precision steel side leakage proof of all welded bags. We can ensure that the liquid filter material containing silicone oil substances, to ensure that it is used in food or paint and other demanding applications. Filter bag optional material: (PO) Polypropylene needle felt, (PE) Polyester needle felt, (NO)nylon monofilament Wood quality and micron: Polypropylene needle felt: 1-200 microns Polyester needle felt: 1-200 micron nylon monofilament: 25-800 microns Filter bag fixed ring material: stainless steel ring, galvanized steel ring, polyester / polypropylene plastic ring Typical application field: -Textile, printing and dyeing, paper industry of various liquid purification. -Food and beverage: process purification and aseptic treatment of beer, liquor, bottled water, tea beverage, dairy products, edible oil and other food additives. -Petrochemical and chemical industry: lubricating oil, aviation coal and various oils, catalysts, viscose, polymer, resin, hydrogen peroxide, chemical fiber in the manufacturing process -Fluid purification, separation and recovery of valuable chemical intermediate products and chemical products. -Paint, paint ink: latex paint, paint raw materials and solvent filtration, printing ink, printing ink and additive filter.

|

|

| Previous:无 | next:无 |

chinese

chinese English

English