-

- solid-liquid separation series

- industrial filter cloth

- filter press filter bag

- centrifuge filter bag

- leaf filter filter bag

- belt type filter press filter cloth

- flat fold filter filter cloth

- vertical disk filter filter bag

- flat filter filter cloth

- drum filter filter cloth

- suction filter filter bag

- liquid filter felt

- liquid filter bag

| Mud Building Materials Industry | |

| 2018/3/29 10:10:36 阅读次数:1416 | |

|

|

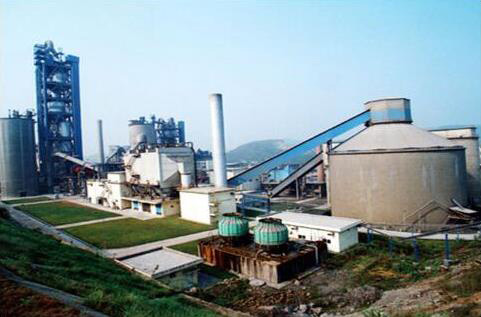

The cement technology mainly has the following dust collecting points: 1. Ash crushing, transportation and storage Limestone is the main raw material for cement production. After entering the plant, limestone has to go through several stages of crushing and then enter into the next process after reserve. There are many dust spots in this process. 2. Dust removal of waste gas from raw material mill There is high humidity in the dust-containing gas in this part, so it is very difficult for the raw material to grind and dedusting, so it is necessary to consider the problem of anti-condensation when selecting the filter material. 3. coal mill system bag dust collector Coal powder gas is a flammable and explosive gas. The bag dust collector for coal grinding must be provided with anti-combustion and explosion-proof measures, and the filter bag must use antistatic filter material. 4. Dust removal by raw material dryer There are two main drying methods: one is to dry simultaneously in the grinding process, that is, the drying process and the grinding process are carried out in the same equipment; the other is to set up a separate drying equipment. The exhaust gas from drying equipment is the main dust emission source in cement plant, especially the clay drying system. The wet content of the system is especially high, the wet content of waste gas is generally more than 15%, and the dew point temperature is above 55 ℃. The concentration of dust is as high as 50 g / Nm ~ (3). It is necessary to use the anti-condensation filter material, at the same time, the body should be used as anticorrosion, heat preservation, temperature automatic detection and adjustment measures, etc. 5, rotary kiln dust removal Sintering is the main technology of cement production, the main pollutant is high temperature dust-bearing gas, the smoke contains a large amount of dust concentration of 30-100g / m3; because of the high chimney, the smoke quantity is large, the concentration is high, the general choice is NOMEX or P84. 6. Dust removal of vertical kiln The dust concentration, wet content and waste gas temperature of flue gas in vertical kiln vary greatly, the bag dust collector must meet the fluctuation of the above wide range, and the selection of filter material should also be paid attention to. 7. Dust removal from cement mill The cement mill releases higher concentrations, sometimes more than 1000 gm / m³, and the filter material should resist a certain amount of erosion. 8.Dedusting of cement packing system Cement packaging system has several dust spots, the original use of a single-machine dust collector, general single-machine dust remover and normal temperature filter can be used. |

|

| Previous:Asphalt smoke industry | next:Filter cloth identification method |

chinese

chinese English

English