-

- solid-liquid separation series

- industrial filter cloth

- filter press filter bag

- centrifuge filter bag

- leaf filter filter bag

- belt type filter press filter cloth

- flat fold filter filter cloth

- vertical disk filter filter bag

- flat filter filter cloth

- drum filter filter cloth

- suction filter filter bag

- liquid filter felt

- liquid filter bag

| High temperature resistant filter Media: PTFE Needle punched felt | |

| 2018/2/20 16:03:03 阅读次数:993 | |

|

|

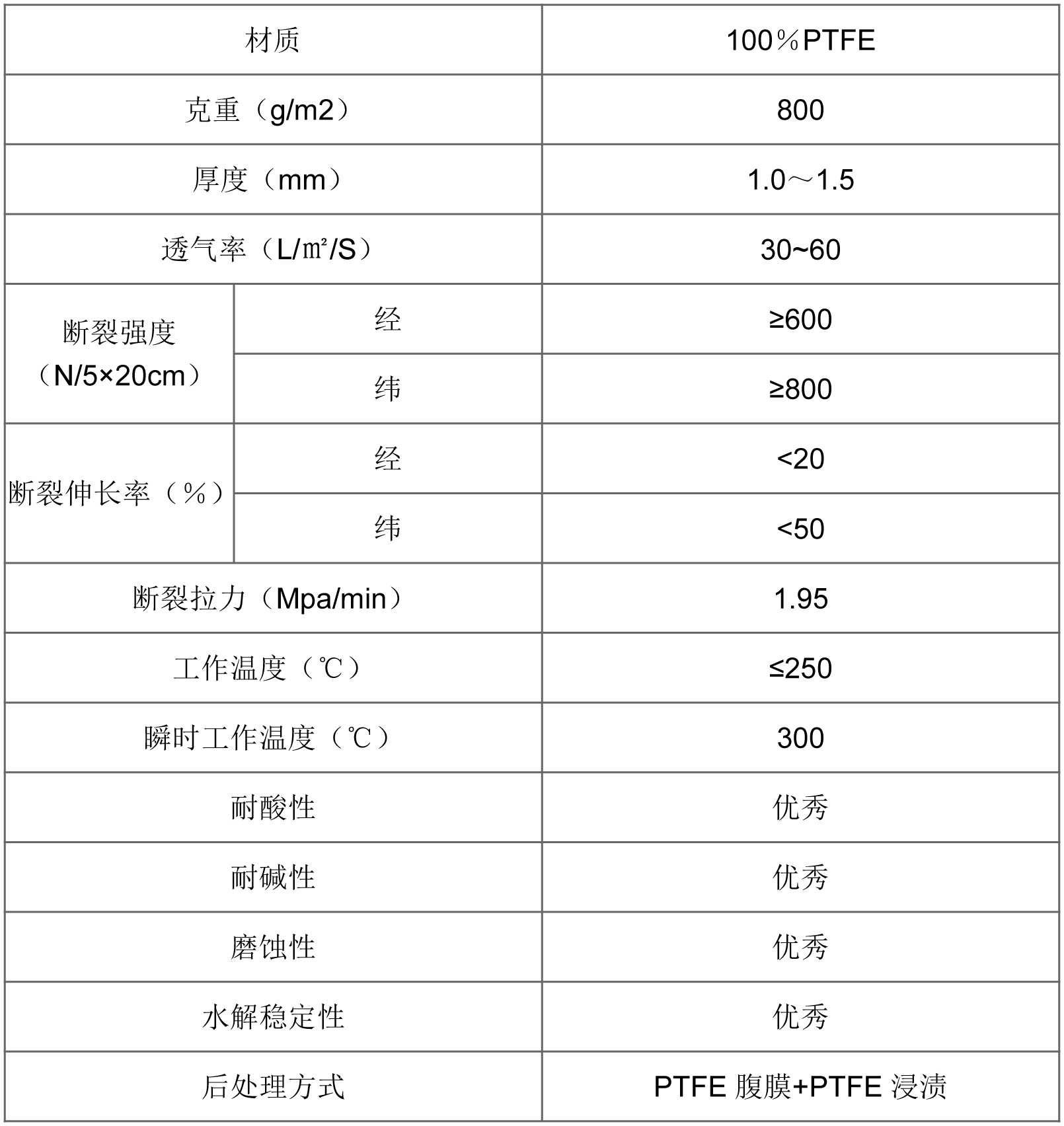

Product profile:PTFE needle felt is a kind of filter material. PTFE fiber is a kind of filtration material made by three dimensional needling. PTFE fiber is a kind of macromolecular linear structure needle felt. Therefore, it has extremely strong resistance to temperature, wear resistance, corrosion resistance, chemical stability, and is widely used in iron and steel. Electricity, waste incineration and other adverse flue gas filtration environment. Product properties: 100% pure PTFE; suitable temperature -210 ℃ to 265 ℃; acid-alkali resistance, corrosion resistance, chemical stability extremely strong; high humidity environment also applicable; aging resistance; no pollution; fabric composition of PTFE short fiber PTFE crimp fiber mixed with other fibers, It can reduce the cost and keep certain non-stickiness. The appearance is pure white. The content is 100% PTFE. The processing time is more than 62 needles per square centimeter, using antistatic agent, using all steel equipment, And must be made of a ground device.) 100%PTFE substrate (made of 500dtex filaments (monofilament). The fabric is plain texture. PTFE substrate may be made according to the strength requirement of the filter material, Different longitude and weft densities are designed, such as: warp 140 / 10 cm, latitudinal 140 / 10 cm ~ (-1) 140 / L, the warp / zonal strength of the base cloth can be greater than 1000NL. Based on the chemical stability of PTFE raw materials, it is the most chemically resistant and stable product of all filter materials. 1, continuous working temperature above 250 degrees, instantaneous temperature 280 degrees. 2, completely not afraid of acid, alkali and oxidation, almost non-flammable. 3.The only fiber that does not age. 4. meet the worst working conditions, with a very long service life, usually in the service life of more than 4 years.

|

|

| Previous:Aramid needle punched felt | next:plate and frame filter press |

chinese

chinese English

English