-

- solid-liquid separation series

- industrial filter cloth

- filter press filter bag

- centrifuge filter bag

- leaf filter filter bag

- belt type filter press filter cloth

- flat fold filter filter cloth

- vertical disk filter filter bag

- flat filter filter cloth

- drum filter filter cloth

- suction filter filter bag

- liquid filter felt

- liquid filter bag

| Glass Fiber Dust Removal Bag | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2019/8/17 10:11:51 阅读次数:609 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass fiber needle felt is a high temperature resistant filter material with reasonable structure and good performance. It not only has the advantages of high temperature resistance, corrosion resistance, dimensional stability, extremely small elongation and contraction rate and high strength, and the felt fiber is single fiber, three-dimensional microporous structure, high porosity and low resistance to gas filtration. It is a high-speed, high-efficiency high-temperature filter material. Compared with other high temperature resistant fiber felts, it has special advantages such as low price and high temperature resistance. However, its running resistance is higher than that of general chemical fiber high-temperature filter materials, and the filtration precision is slightly lower. Application: Glass fiber needle felt can be widely used in high temperature flue gas filtration of various industrial furnaces such as chemical industry, steel, metallurgy, carbon black, power generation and cement. It is suitable for various bag filters such as pulse cleaning and high-speed blowback cleaning.

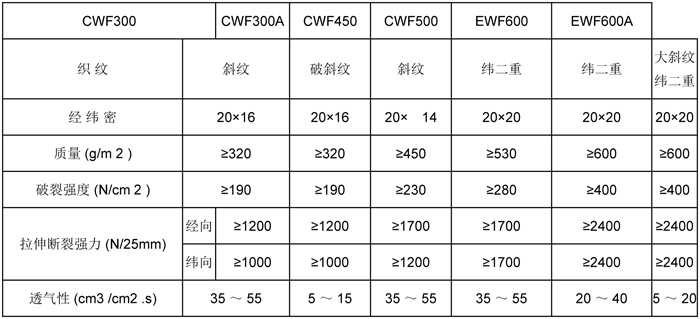

Continuous glass fiber filter cloth

Glass fiber is an inorganic fiber whose main component is SiO2 . It is obtained by melting the glass frit at a temperature of 1300 to 1600 ° C, spinning from a molten state and rapidly quenching it. The specific gravity is 2.54g/cm3 , and the tensile strength of the raw yarn is 160 to 275kg/m2 . The filter material is generally made of C glass (ie, medium alkali glass or calcium soda lime silicate glass) and E glass (ie, alkali-free glass or aluminoborosilicate glass).

The disadvantage of glass fiber is that the folding resistance is poor, and post-treatment such as PTFE impregnation is required to improve the performance. The fiberglass is not resistant to folding, the fabric filter material is low-pressure anti-blowing, and the needle felt is pulsed. The glass fiber expanded filter cloth with a square weight of more than 700 grams can be cleaned by rotary backflushing or low pressure pulse blowing.

Continuous glass fiber filter cloth

Glass fiber expanded yarn filter cloth

The glass fiber expanded yarn filter cloth is a new type of fabric developed on the basis of continuous glass fiber flat filter cloth. The difference from the continuous glass fiber filter cloth is that the weft yarn is composed of all or part of the puffed yarn, because the yarn is fluffy. strong covering capacity, permeability, and thus improve the filtration efficiency, reduce filtration resistance and a high dust removal efficiency, up to 99.5 % or more, the filtration rate in the 0.6 ~ 0.8 yards / second.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Previous:Film-covered dust bag | next:Aramid dust bag | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

chinese

chinese English

English